We’re Committed To Quality

J.M. Fabrication Company LLC has been a trailblazer in the aerospace and defense industries since its inception in 1979. Headquartered in Arlington, Texas, this privately held company has a rich history of offering its clientele custom fabrication and engineering services, forging a legacy of excellence.

Mission and Vision

At the core of J.M. Fabrication lie its mission and vision, which drive the company to achieve exceptional results. The company’s mission is to provide superior quality products, timely delivery, and outstanding customer service while consistently focusing on meeting the needs and demands of its customers. J.M. Fabrication’s vision is to become a nationally recognized leader in custom fabrication and engineering services for the aerospace and defense industries by fostering innovation, embracing cutting-edge technologies, and nurturing an exceptional team of professionals.

Quality Certifications

J.M. Fabrication’s commitment to excellence is evident in the quality certifications it has obtained, including AS9100 and ISO9001. These certifications ensure that their products and services meet the highest quality and safety standards while demonstrating their dedication to continuous improvement. Furthermore, J.M. Fabrication is ITAR (International Traffic in Arms Regulations) registered, which permits them to work with sensitive defense-related products and services. They also adhere to the NIST (National Institute of Standards and Technology) and CMMC (Cybersecurity Maturity Model Certification) guidelines to ensure the protection of controlled unclassified information.

Why Choose JM Fabrication?

There are several compelling reasons to choose J.M. Fabrication for your next project:

Experience: With decades of experience in the aerospace and defense industries, J.M. Fabrication has an exceptional team of professionals who can bring your vision to life.

Quality: The company’s commitment to maintaining industry-leading quality certifications showcases its dedication to providing top-notch products and services.

Security: J.M. Fabrication’s adherence to ITAR, NIST, and CMMC guidelines demonstrates its focus on safeguarding sensitive information and compliance with government regulations.

Customer-centric Approach: J.M. Fabrication builds long-lasting relationships with its clientele by prioritizing customer satisfaction and striving to exceed expectations.

Get Started on Your Next Project

When you choose J.M. Fabrication Company LLC for your next project, you are partnering with a company with a proven track record of excellence in the aerospace and defense industries. Their mission, vision, quality certifications, and customer-centric approach make them ideal for your custom fabrication and engineering needs. Reach out to J.M. Fabrication today to discuss your project and experience the difference that their expertise and commitment to excellence can make.

The company is located at 415 Duncan Perry Road, Arlington Texas 76011, and office hours are Monday through Thursday, 8:00 am to 5:00 pm. You may contact us by email at quotes@jmfab.com or by phone at 817-652-0526.

We look forward to serving you!

Services

What we Provide

Electromechanical Assembly

Reverse Engineering

Mechanical Assembly

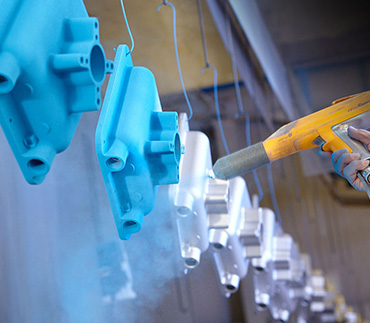

Mil Std Prime Paint Powder Coating and Silk Screening

Sanding and Deburring

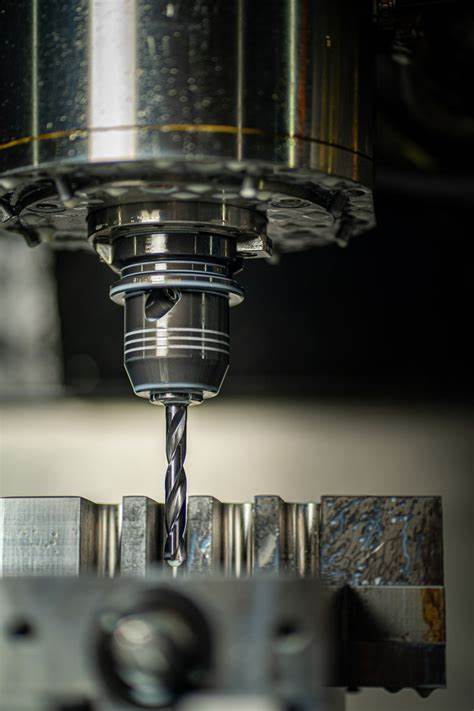

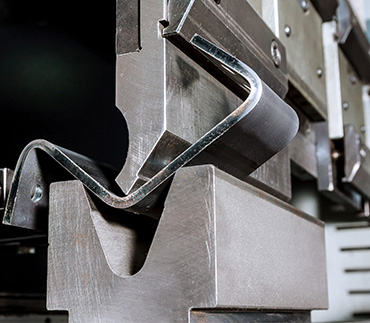

Precision Sheet Metal Fabrication, Forming, and Punching