- quotes@jmfab.com

- 817-652-0526

- 415 Duncan Perry Rd, Arlington Texas 76011

Why Zero Defects and On-Time Delivery Matter in Aerospace and Defense Manufacturing: Insights from JM Fabrication In the aerospace and defense industries, quality and on-time delivery are crucial factors that can make or break a manufacturer’s reputation. JM Fabrication understands the importance of these factors and has made a commitment to delivering high-quality products with… Continue reading The Importance of Quality and On-Time Delivery in Aerospace and Defense Manufacturing

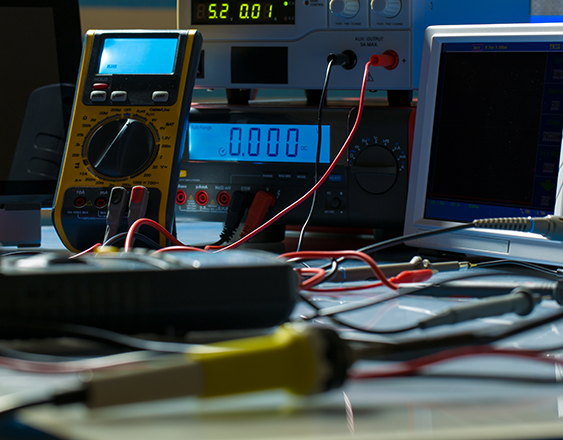

The Importance of Traceability and Audit Preparation in Aerospace Manufacturing Calibration Calibration is a critical aspect of maintaining quality control in any industry, but it’s particularly important in the aerospace industry. Precision and accuracy are essential in aerospace, and even small deviations can have significant consequences, such as product defects, non-compliance, and safety issues. This… Continue reading The Critical Importance of Regular Calibration in the Aerospace Industry

The Role of Quality Control in Achieving MIL-STD-186 Standards. At JM Fabrication, we pride ourselves on maintaining the highest standards in protective finishing for critical applications. One such example is our compliance with MIL-STD-186, Revision F, a key military standard that governs the manufacturing process of protective finishing for Army missile weapon systems. In this… Continue reading Meeting the Demands of MIL-STD-186: How JM Fabrication Ensures Top-Quality Protective Finishing

Boosting Efficiency, Quality, and Market Entry with JM Fabrication’s DFM Expertise and Capabilities. In an era of relentless competition, companies must improve their manufacturing processes and embrace novel approaches to stay ahead. JM Fabrication stands out as a supplier with a focus on Design for Manufacturing (DFM), dedicated to refining operations and reducing costs while… Continue reading Six Advantages of Partnering with JM Fabrication for Streamlined Manufacturing and Cutting-Edge Coating Solutions