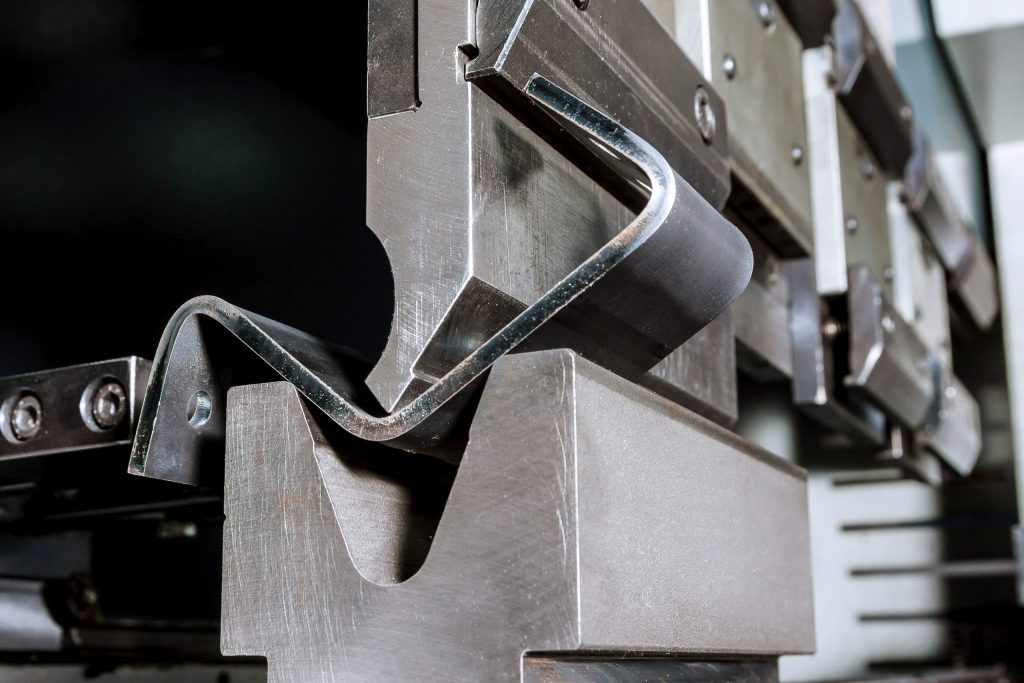

Precision Sheet Metal Fabrication, Forming and Punching

CNC punching is one of the procedures used in sheet metal manufacturing. We use CNC punch presses with multi-tool turrets, which provide setup flexibility and quick turnaround times. We can quickly configure and operate components, especially those that require conventional feature sizes. Aluminum, steel, stainless steel, galvanized steel, copper, and titanium are typical raw materials that we punch. We can handle large volume production runs or rapid turn prototyping due to our wide tooling inventory.

The most advanced precision sheet metal fabrication equipment is available in the sheet metal fabrication shop. We provide AMADA CNC-controlled punching machines with high-speed punching on an immediate production basis in both mechanical and hydraulic versions. Using autonomous material loaders, our precision sheet metal punching machines are capable of operating nearly unsupervised for up to four hours between pallet changes, which boosts production.

Special forming tools like louvres, countersinks, and extrusions may be used on both hydraulic and mechanical sheet metal punching machines, which eliminates labor-intensive secondary procedures. The completely rotating punching heads on all of JM Fabrication’s sheet metal punching machines allow most tooling to be adjusted to any punching angle. With little lead time and typically no tooling costs, this technique offers you a wide range of hole and shaping possibilities.

Punch forming is performed on-site, allowing for the quick delivery of sheet metal components. Our operators are fully equipped with expertise in punch forming prototypes and small quantities of finished goods.